Explore Our Extensive Workshop Facilities at Ivan Dutton Limited

State-of-the-Art Workshops and Dyno Cell

Comprehensive Body Shop and Toolroom

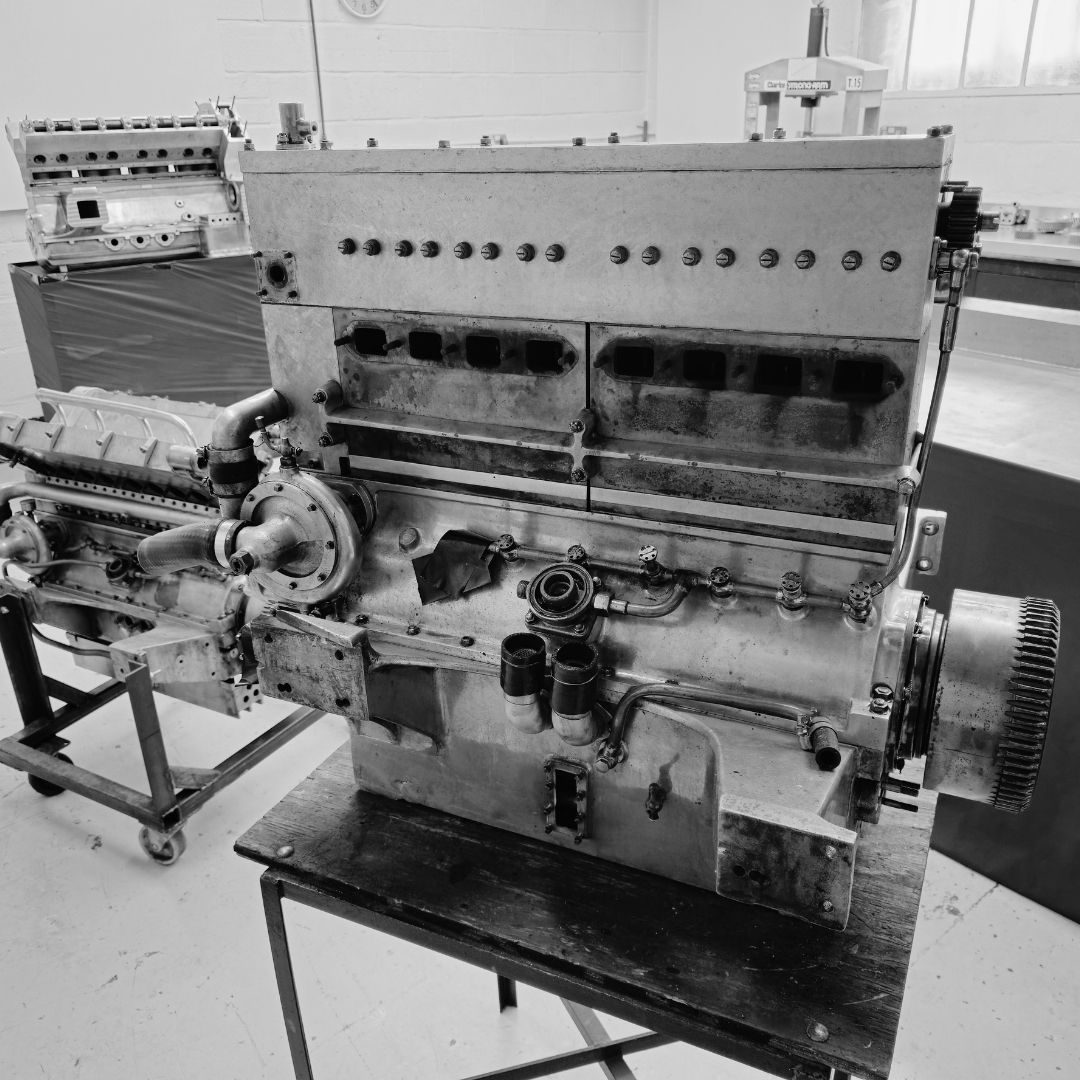

Our workshops, dyno cell, body shop, toolroom and car stores occupy nearly 20,000 square feet (1,850 m2) of buildings on our farm in rural Buckinghamshire. Set in the ideal environment to enjoy vintage motoring with winding lanes and great pubs. This is also the "silicone valley of the motor-racing industry" with many Formula One teams and Silverstone nearby. We regularly have 20 Bugattis on site undergoing restoration, our showroom holds parts, displays and Bugatti miscellany alongside Bugattis looking for a new home.

Our workshop ethos essentially follows two distinct policies. Firstly, we invest as necessary in patterns and tooling for high quality new parts which exactly match the originals. These we make available as raw castings or forgings, finish machined parts or as sub-assemblies.

Secondly, we keep abreast of developments in materials and manufacturing processes which allow us to produce superior parts which do not impact visually on the cars but significantly improve the longevity and driveability of Bugatti cars of all models. Examples being modern replacement paper element oil filters which fit inside the original Bugatti filter body providing a major improvement in oil filtration and an overdrive conversion for Type 43, 44, 49, 40 and 57 Bugattis. This helps to compensate for the higher average speeds now achievable using motorways without sacrificing flexibility on country lanes. Sintered clutch conversions for most Bugatti models are also carried out. Whilst not altering the original metal to metal concept, this type of clutch requires very little maintenance and gives increased durability, very suitable if the car is entered for competition.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.